Process characteristics and benefits: grinding oil/ metal swarf recycling

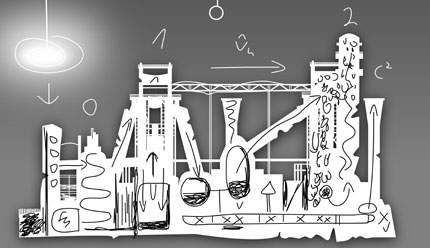

Process characteristics

- De-oiling of metal swarfes from coarse to powdery consistency

- Recovery of grinding oil and cooling lubricant

- De-oiling to a residual oil content of up to 0.01%

- Reusability of grinding oils and cooling lubricants

Your benefits at a glance

Automated and direct process

Filling of the grinding sludges/ -swarfes

Filling of the grinding sludges/ -swarfes

Discharge of the de-oiled metal swarfes

Discharge of the de-oiled metal swarfes

Conical extraction vessel

Simple and complete emptying

Simple and complete emptying

Optimal heat transfer by direct contact to the heated vessel surface

Optimal heat transfer by direct contact to the heated vessel surface

Optimized drying of the metal swarfes

Optimized drying of the metal swarfes

Glazing/ suspension of solid particles

Minimized remnant oil content (up to 0.01%)

Minimized remnant oil content (up to 0.01%)

Reduction of extraction time

Reduction of extraction time

Optimized and equal de-oiling even with angled and unfavorable swarf forms

Optimized and equal de-oiling even with angled and unfavorable swarf forms

Handling

No elaborate filling/ emptying of the metal swarfes

No elaborate filling/ emptying of the metal swarfes

No elaborate placement, transport of the extraction filter baskets

No elaborate placement, transport of the extraction filter baskets

Minimized cleaning effort, since cleaning of the filter baskets is not required

Minimized cleaning effort, since cleaning of the filter baskets is not required

Return on invest

Optimized throughput

Optimized throughput

Lower personnel costs

Lower personnel costs

Lower operational costs

Lower operational costs

Safety aspects

No risk at discharging of potentially explosive metal dust

No risk at discharging of potentially explosive metal dust

No elaborate discharging lock for filter baskets required

No elaborate discharging lock for filter baskets required

Reduced air emissions through heat exchange

Reduced air emissions through heat exchange

DE

DE

EN

EN